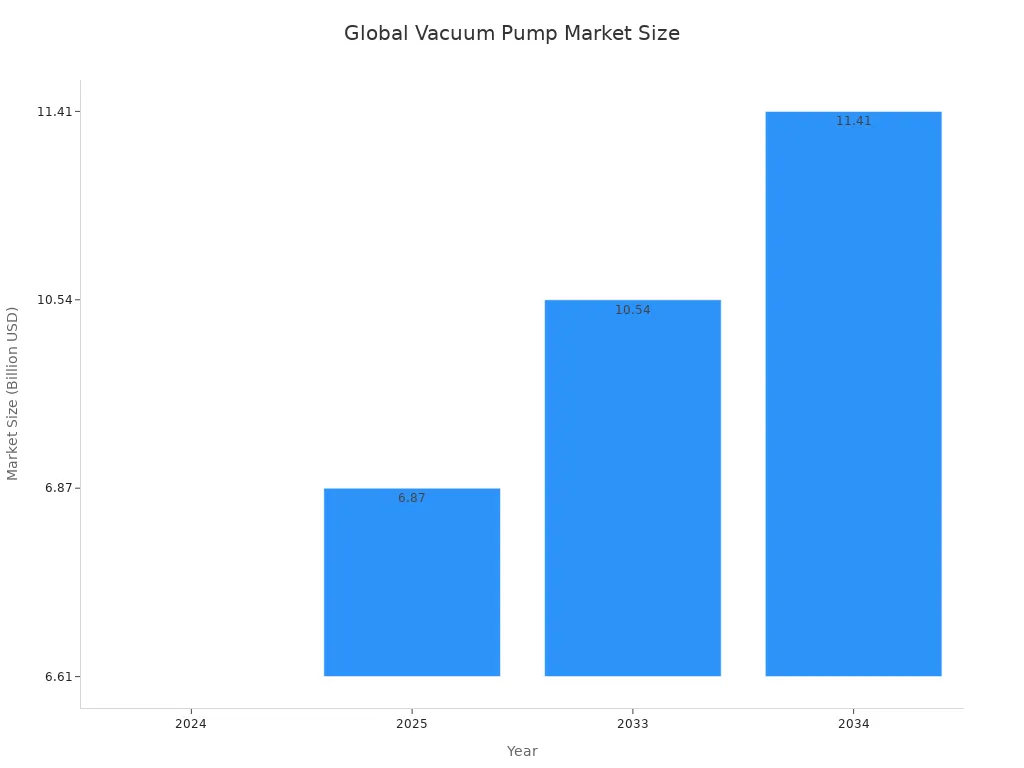

A Roots pump creates a vacuum using two counter-rotating, lobed rotors. These rotors trap gas at the inlet and transport it across the pump's housing without internal compression. This continuous, high-speed transfer of gas molecules reduces pressure, achieving vacuums as low as 10⁻⁵ mbar with proper backing. The global vacuum pump market's steady growth highlights its importance.

Many critical sectors rely on the Roots vacuum pump, including:

• Semiconductor Industry: For processes like thin-film deposition and etching.

• Chemical Industry: In applications such as distillation and drying.

• Pharmaceutical Industry: For vacuum filtration and freeze-drying.

The Inner Workings of a Roots Vacuum Pump

A Roots vacuum pump operates on a simple yet highly effective principle. Its internal mechanism moves gas from an inlet to an outlet without compressing it inside the pump chamber. This process relies on the synchronized movement of several key parts working in perfect harmony.

The Four-Step Operating Cycle

The pumping action happens in a continuous, four-step cycle that repeats thousands of times per minute. Modern rotors can spin at speeds from 3,000 to 6,000 RPM. This high speed allows the pump to move large volumes of gas very quickly.

Intake: As the two lobed rotors spin in opposite directions, a pocket of space opens at the pump's inlet. Gas from the vacuum chamber flows into this expanding volume.

Isolation: The tip of a rotor lobe passes the inlet port. This action traps a specific volume of gas between the rotor and the pump's housing.

Transfer: The trapped pocket of gas is then swept across the inside of the housing toward the outlet. A key feature of the Roots vacuum pump is that it does not compress this gas during transfer. This non-contact, oil-free operation makes it insensitive to small amounts of dust or water vapor.

Exhaust: The rotor continues to turn, exposing the pocket of gas to the outlet port. The gas then expands into the exhaust line, where a backing pump removes it from the system. This cycle repeats, continuously moving gas from the inlet to the outlet and lowering the system pressure.

Note: While highly efficient for many gases, the suction ability of a Roots pump is lower for very light gases like hydrogen when compared to other pump types.

Key Components and Their Functions

The reliable performance of a Roots pump depends on a few critical components engineered with high precision.

Rotors: The pump features two interlocking, lobed rotors (often shaped like a figure-eight). The shape, or profile, of these lobes directly impacts performance. Different designs offer trade-offs between pumping speed and efficiency. Helical rotors, for example, help reduce pressure pulsation and operational noise.

| Rotor Profile Type | Pumping Speed Advantage | Volume Utilization Rate |

|---|---|---|

| Novel elliptical | 1.5 times higher than top elliptical | High |

| Top elliptical | Standard performance | Approaches 55% |

Housing (Casing): This is the outer body that encloses the rotors. It is built to withstand the pressure differences between the vacuum system and the atmosphere. The material used for the housing and rotors depends on the application's demands for corrosion resistance, strength, and cost.

| Material | Key Advantages | Common Applications |

|---|---|---|

| Cast Iron | High strength, good wear resistance, cost-effective. | General industrial, chemical, and food processing. |

| Stainless Steel | Excellent corrosion resistance, hygienic properties. | Pharmaceutical, semiconductor, and medical equipment. |

| Aluminum Alloy | Lightweight, good thermal conductivity. | Aerospace, automotive, and portable pump systems. |

Timing Gears: Located outside the pumping chamber, timing gears are essential. They synchronize the two rotors, ensuring they spin in opposite directions without ever touching each other or the housing. This synchronization is fundamental to the pump's non-contact operation.

Shaft Seals: Seals prevent air from leaking into the vacuum chamber and stop lubricants from contaminating the process. The choice of seal depends on the required vacuum level and application.

| Seal Type | Mechanism | Best For |

|---|---|---|

| Labyrinth Seal | Uses a complex path to stop flow; no contact. | High-speed applications where zero wear is needed. |

| Mechanical Seal | Uses two highly polished, spring-loaded faces. | High-pressure, high-temperature, and low-leakage needs. |

| Magnetic Fluid Seal | Uses a magnetic fluid to create a perfect barrier. | High-vacuum applications requiring zero leakage. |

The Importance of Precise Clearances

The term "clearance" refers to the tiny, calculated gaps between the rotors and between the rotors and the housing. These gaps are the secret to the pump's success. They allow the rotors to spin at high speeds without friction, which provides many advantages:

Fast start-up

Low power consumption

High pumping speed

Low operation and maintenance costs

However, these clearances must be managed perfectly. During operation, the pump generates heat. This heat causes the metal components to expand, a process known as thermal expansion. As the rotors and housing expand, the clearances between them shrink.

Warning: If clearances become too small due to thermal expansion or incorrect assembly, the rotors can make contact with each other or the housing. This leads to friction, component damage, increased motor load, and potential pump seizure. Conversely, clearances that are too large allow gas to leak backward from the outlet to the inlet, which severely reduces the pump's efficiency.

Proper engineering and material selection ensure that a Roots vacuum pump maintains optimal clearances across its operating temperature range, delivering reliable and efficient performance.

System Configuration: Backing vs. Multi-Stage Pumps

A Roots pump is a powerful booster, but it cannot work alone. It requires a specific system configuration to reach its full potential. The pump moves gas efficiently but does not compress it enough to exhaust directly into the atmosphere. This limitation requires the use of a backing pump or a multi-stage arrangement.

Why a Backing Pump is Necessary

A Roots pump needs a backing pump to handle its exhaust. The backing pump connects to the outlet of the Roots pump. It takes the transferred gas and compresses it to atmospheric pressure, completing the evacuation process. This partnership allows the system to achieve deep vacuums effectively. The choice of backing pump depends on the specific application and desired vacuum level.

Did You Know? The backing pump is also called a primary pump because it does the final work of removing gas from the system.

Common types of backing pumps include:

Two-stage rotary vane pumps

Oil-sealed mechanical pumps

Two-stage slide valve mechanical pumps

Liquid ring vacuum pumps

How Multi-Stage Pumps Work

For applications demanding extremely low pressures, engineers connect multiple pumps in series. This creates a multi-stage Roots Vacuum Pump system. In this setup, the outlet of the first pump feeds into the inlet of the second, and so on. Each successive stage lowers the pressure further. A final backing pump is still needed at the end of the chain to exhaust the gas to the atmosphere.

These powerful systems are vital for high-tech and demanding industries. Key applications include:

Semiconductor Manufacturing: For processes like Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD), and etching.

Aerospace: In space simulation chambers and component testing.

New Energy: For manufacturing solar panels and batteries.

The Roots vacuum pump excels at high-speed gas transfer rather than internal compression. Its simple, non-contact design creates a powerful booster for clean, high-throughput applications. Modern pumps now integrate energy-efficient motors and smart sensors, pushing performance even further for demanding industries that require reliable and efficient vacuum systems.

Post time: Oct-28-2025