Factory Supply Vacuum Packing - Piston Filling Machine – Joysun Detail:

Piston Filling Machine

Product Detail:

Quick Details:

Condition: New Application: Bottle Plastic Processed:

Blow Mould Type: Automatic: Place of Origin: Shanghai China (Mainland)

Brand Name: Joysun Model Number: USE:

Industrial Use: Beverage Material: Metal Metal Type: Steel

Specifications

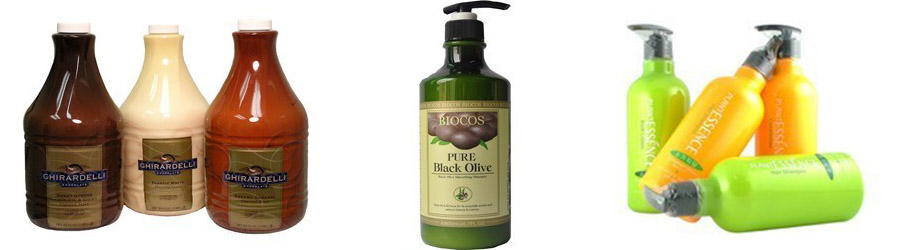

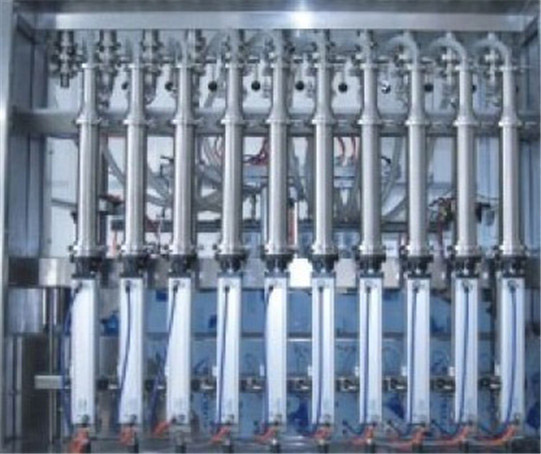

This is a timed flow volumetric filling machine which is controlled by the piston so that the filling precision is ensured. The bulk supply of piston filling machine is pumped into a holding tank above a set of pneumatically operated valves, each one of which is independently timed by the master computer. Thus, the exact amount of liquid will be forced into the container through gravity.

Characteristics

1. In a single filling cycle, this filling machine can achieve the maximum filling volume through several times filling.

2. The interface and PLC control system is user-friendly.

3. A pneumatic valve is designed to prevent bottles from nozzle dripping.

4. Servo nozzle height (Submersible filling is optional)

5. No materials/no fill (suspend operation)

6. No bottle/no fill (suspend operation)

7. Encounter obstruction /no fill (suspend operation)

Technical Specifications

| Model | Filling valve | Filling volume (ml) | Production capacity (bph) | Bottle diameter(mm) | Bottle height(mm) | Power (kw) |

| ZG-4 | 4 | 20-1000 | 1000-2500 | Ø 20- Ø 150 | 160-300 | 3.5 |

| ZG-8 | 8 | 20-1000 | 2500-4000 | Ø 20- Ø 150 | 160-300 | 3.5 |

| ZG-12 | 12 | 20-1000 | 4000-6000 | Ø 20- Ø 150 | 160-300 | 3.5 |

Product detail pictures:

Related Product Guide:

owing to excellent assistance, a variety of high quality products and solutions, aggressive costs and efficient delivery, we take pleasure in an excellent popularity amongst our customers. We are an energetic business with wide market for Factory Supply Vacuum Packing - Piston Filling Machine – Joysun , The product will supply to all over the world, such as: Philippines, Miami, moldova, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!