A Umshini Wokugcwalisa Imiphongolo engu-5 Galloniza ngezinhlobo ezimbili eziyinhloko: okuzenzakalelayo kanye ne-semi-automatic. Uhlobo ngalunye lunikeza izidingo ezihlukene zokukhiqiza ngokusekelwe ezingeni lokubandakanyeka komsebenzisi.

Izigcwalisi ezizenzakalelayo zisingatha yonke inqubo yokugcwalisa ngokuzimela.

Ama-semi-automatic fillers adinga opharetha ukuthi abeke imiphongolo futhi aqale umjikelezo ngamunye.

Okuthathwayo Okubalulekile

Izihlungi ezizenzakalelayo zisebenza kahle kakhulu ezimbonini ezinkulu ezenza imikhiqizo eminingi. Bagcwalisa imiphongolo ngokushesha futhi badinga abasebenzi abambalwa.

Ama-semi-automatic fillers alungeleamabhizinisi amancane. Abiza kancane ukuwathenga futhi kulula ukuwashintsha emikhiqizweni eyahlukene.

I-filler engcono kakhulu kuwe incike ekutheni mingaki imiphongolo okudingeka uyigcwalise nokuthi ingakanani imali ofuna ukuyisebenzisa.

Ukuqhathanisa Okuzenzakalelayo vs. I-Semi-Automatic Fillers

Ukukhetha isigcwalisi esifanele kuncike ekuhlaziyeni ngokucophelela izidingo zakho zokukhiqiza. Izinto ezifana nesivinini, izindleko, abasebenzi, nokuvumelana nezimo zizoqondisa isinqumo sakho. Ake sihlukanise umehluko obalulekile phakathi kwesistimu ezenzakalelayo ne-semi-automatic.

Isivinini sokukhiqiza kanye nevolumu

Isivinini sokukhiqiza ngokuvamile siyisici esibaluleke kakhulu esihlukanisa lezi zinhlobo ezimbili zemishini.

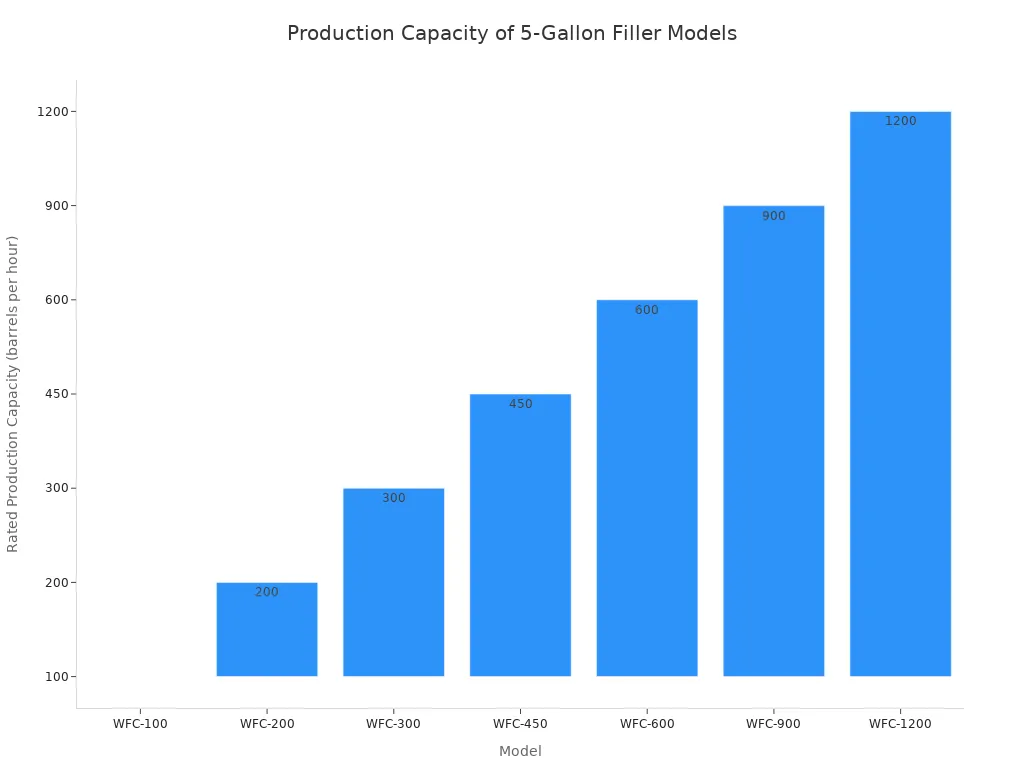

Ama-Automatic Fillers: Le mishini yakhelwe ukukhiqizwa kwevolumu ephezulu. Asebenza ngokuqhubekayo ngokuphazamiseka okuncane, afinyelela amazinga okukhiphayo ahlaba umxhwele. Amanye amamodeli athuthukile angagcwalisa imiphongolo efika ku-1,200 ngehora (BPH), kanti amanye emugqeni ogcwele wokukhiqiza angafinyelela isivinini esingu-2,000 BPH noma ngaphezulu. Amasistimu e-rotary anesivinini esiphezulu alungele ukusebenza kwesilinganiso esikhulu esidinga ukukhulisa ukusebenza kahle.

Ama-Semi-Automatic Fillers:Lezi zihlungi zinikeza isivinini esihle sokusebenza semisebenzi emincane ukuya kwemaphakathi. Umsebenzisi ulawula ijubane mathupha, okuyinto ehamba kancane ngokwemvelo kunenqubo ezenzakalelayo ngokugcwele. Ziyisixazululo esingabizi kakhulu samabhizinisi angadingi ukuphuma okuphezulu kwesistimu ezenzakalelayo.

Inketho efanele incike ngokuphelele kumthamo wakho wokukhiqiza.

Ukukhiqizwa Kwezinga Elincane:Ama-Startups namabhizinisi amancane avame ukuthola imishini ye-semi-automatic ibe inketho engabizi kakhulu.

Ukusebenza Kwesikali Esimaphakathi:Amabhizinisi akhulayo azuza ezinhlelweni ezizenzakalelayo ezilinganisela ezishintshayo nokulawula okwenziwa ngesandla.

Ukukhiqiza Okuphezulu:Izinsiza ezinkulu ezimbonini zamakhemikhali, ezekhemisi, noma ezifaka amabhodlela amanzi zithembele emishinini ezenzakalelayo ngokuphelele ukuze kwandiswe isivinini nokusebenza kahle.

Izindleko Zokuqala vs. I-ROI Yesikhathi Eside

Ukutshalwa kwezimali kuyingxenye ebalulekile yenqubo yokuthatha izinqumo. Nakuba izindleko zokuqala zihluka kakhulu, imbuyiselo yesikhathi eside ku-investimenti (ROI) isitshela indaba ephelele.

Umshini Wokugcwalisa Imigqomo Ozenzakalelayo we-5 Gallon umelela ukutshalwa kwezimali okubalulekile kwangaphambili, ngezintengo zomugqa ogcwele wokukhiqiza ngokuvamile ukusuka ku-$3,500 kuya ku-$45,000. Lezi zindleko zingabonakala ziphakeme, kodwa zivula ukonga okukhulu kwesikhathi eside.

Izinkampani eziningi zithola imbuyiselo ekutshalweni kwezimali zokugcwalisa okuzenzakalelayo phakathi nezinyanga eziyi-18 kuye kwezingama-24. Le mbuyiselo esheshayo ivela ekwehlisweni okukhulu kwezindleko zabasebenzi, ukumoshwa okuncane kwezinto ezibonakalayo, nokusebenza kahle okuphezulu kokukhiqiza.

Isibonelo, izikhungo ezithuthukela emugqeni ozenzakalelayo ngokuphelele zinganciphisa izindleko zabasebenzi cishe ngo-40%. Iphrosesa eyodwa yokudla yosayizi omaphakathi yonga cishe u-$326,000 ngonyaka emholweni wodwa ngemva kokufaka izigcwali ezizenzakalelayo, iphinde ibuyise ukutshalwa kwayo esikhathini esingaphezu konyaka nesigamu.

Izidingo Zabasebenzi kanye Neqhaza Lomsebenzi

Izinga lokubandakanyeka komuntu liwumehluko oyinhloko phakathi kwalezi zinhlelo ezimbili, ezithinta ngokuqondile izindleko zabasebenzi kanye nezindima zokusebenza.

Ulayini we-semi-automatic udinga ukuthi o-opharetha babambe iqhaza elibonakalayo kule nqubo. Ulayini owodwa ungase udinge izisebenzi ezi-4 kuya kweziyisi-6, okuholela ezindlekweni zomsebenzi zaminyaka yonke ezingadlula ama-$200,000. Izibopho zomsebenzisi zibanzi futhi zihlanganisa:

Ukubeka imiphongolo engenalutho endaweni yokugcwalisa.

Ukuqala umjikelezo wokugcwalisa umgqomo ngamunye.

Ukuqapha inqubo yamaphutha.

Ukusebenzisa amalebula nokuhambisa imiphongolo egcwele esiteshini esilandelayo.

Ukwenza ukulungisa nokuhlanza umshini okulula.

Ngokuphambene, umshini wokugcwalisa umshini wokugcwalisa we-Gallon we-5 Gallon ozenzakalelayo unganciphisa isidingo sabasebenzi kubaphathi abayi-1-2 ngomugqa ngamunye. Amanye amasistimu amasha asike abasebenzi abadingekayo ngesigamu uma kuqhathaniswa nemigqa emidala. Iqhaza lomsebenzisi liyashintsha lisuka emsebenzini wezandla liye ekugadweni, ligxile ekuqapheni isistimu, ekuphatheni izilungiselelo, nasekubhekaneni nanoma yiziphi izexwayiso. Lokhu kuzenzakalela kungaholela ekongeni kwabasebenzi ngonyaka okungu-$58,000 kuya ku-$92,000 ngomugqa ngamunye.

Ukugcwalisa Ukunemba Nokungaguquguquki

Ukungaguquguquki kuyisihluthulelo sekhwalithi yomkhiqizo, isithunzi somkhiqizo, kanye nenzuzo. Amasistimu azenzakalelayo anikeza inzuzo ecacile kule ndawo.

Amasistimu e-semi-automatic ancike ekunakeni komsebenzisi nesigqi. Lesi sakhi somuntu sethula amandla aphezulu ephutha nokungahambisani. Imishini ezenzakalela ngokugcwele, nokho, isebenza ngokunemba okulawulwa yikhompyutha, iqinisekisa ukuthi umgqomo ngamunye ugcwaliswa ngezinga elifanayo ncamashi ngaso sonke isikhathi. Lo mehluko ubonakala emazingeni okukhubazeka.

| Isici | I-Semi-Automatic Systems | Amasistimu Okuzenzakalelayo Ngokugcwele |

|---|---|---|

| Isilinganiso Sesici | 3-5% | 1-2% |

| Ukuvumelana | Phansi | Kwandiswa |

Ngisho nokungalungile okuncane kungase kube nomthelela omkhulu wezezimali.

Ukugcwalisa ngokweqile kuholela ekulahlekelweni okubalulekile komkhiqizo ezinkulungwaneni zamayunithi, okulimaza ngokuqondile iphuzu elibalulekile. Ukugcwalisa kancane kungalimaza ukwethenjwa kwekhasimende, kuholele ekubuyiselweni komkhiqizo, futhi kudale nezinkinga zomthetho uma imikhiqizo ingahlangabezani nesisindo esilawulayo nezidingo zevolumu.

Ngokunciphisa iphutha lomuntu, Umshini Wokugcwalisa Imigqomo engu-5 Gallon onokuzenzakalela okugcwele uvikela kokubili umkhiqizo wakho kanye nenzuzo yakho.

Izidingo ze-Footprint ne-Space

Ubukhulu bezinto zokusebenza buwukucatshangelwa okungokoqobo kwanoma yisiphi isikhungo.

Ama-Automatic Fillers: Ulayini ozenzakalelayo ophelele uwuhlelo oludidiyelwe oluvame ukuhlanganisa ama-conveyors, ama-de-palletizer, ama-cappers, namalebula. Lokhu kudinga inani elibalulekile lendawo yaphansi eqondile kanye nokuhlelwa kwesikhungo ngokucophelela.

Ama-Semi-Automatic Fillers: Lezi ngokuvamile ezincane, imishini ezimele. Ukwakheka kwazo okuhlangene kunikeza ukuguquguquka okukhulu, okuzivumela ukuthi zibekwe ezindaweni ezinendawo elinganiselwe noma zihlanganiswe nezakhiwo ezikhona kalula.

Ukuvumelana nezimo kanye nesivinini sokushintsha

Uma ibhizinisi lakho likhiqiza imikhiqizo eminingi noma lisebenzisa osayizi abahlukene beziqukathi, ukuguquguquka kubalulekile. Lapha, ama-semi-automatic fillers avame ukuba nesandla esiphezulu.

Imishini ye-semi-automatic ngokuvamile ilula futhi iyashesha ukushintsha isuka komunye umkhiqizo iye komunye. Ukuhlanza kuqondile, futhi ukulungiswa kosayizi abahlukene bemiphongolo kuvame ukuba lula. Lokhu kubenza bafaneleke ezimbonini ezifana neziphuzo zezandla noma amakhemikhali akhethekile adinga ukukhiqizwa okufushane okuvame ukwenziwa.

Izihlungi ezizenzakalelayo ziyizingcweti zokukhethekile, eziklanyelwe ukugijima okude, okungaphazamiseki komkhiqizo ofanayo. Nakuba amasistimu esimanje enezici zokusheshisa izinguquko, inqubo ngokuvamile iyinkimbinkimbi futhi idla isikhathi.

I-Changeover Comparison

| Isici | I-Semi-Automatic Filler | Ukugcwalisa Okuzenzakalelayo |

|---|---|---|

| Isivinini Sokushintsha | Ngokuvamile ngokushesha futhi kulula | Kungaba yinkimbinkimbi futhi kudle isikhathi |

| Ukuvumelana nezimo | Iphezulu, ilungele ukugijima okufushane | Okuphansi, okudizayinelwe ukugijima okude |

| Kuhle kakhulu | Imikhiqizo yangokwezifiso, ama-SKU amaningi | Ivolumu ephezulu, imigqa yomkhiqizo owodwa |

Abakhiqizi beziphuzo ezincane kanye nezinkampani ze-nutraceutical zizuza kakhulu ekuguquguqukeni kwama-semi-automatic fillers, njengoba kuvumela ukuthi bakhiqize amaqoqo amancane futhi bahlole ukuhlukahluka komkhiqizo omusha ngaphandle kokunciphisa okukhulu.

Okusungulwe Okubalulekile Komshini Wokugcwalisa Imiphongolo engu-5 Gallon ngo-2025

Ubuchwepheshe be-barrel fillers buthuthuka njalo. Ngo-2025, izinguquko ezimbalwa ezibalulekile zizokwenza le mishini ihlakaniphe, ihlanzeke, futhi isebenze kahle. Lokhu kuthuthukiswa kusiza amabhizinisi athuthukise ukukhiqiza futhi aqinisekise ikhwalithi yomkhiqizo.

I-Smart Controls kanye ne-IoT Integration

Izigcwalisi zesimanje ziyahlakanipha kakhulu nge-Intanethi Yezinto (IoT). Izinkampani zihlanganisa izinzwa namamodeli okufunda ngomshini emishinini yazo. Lobu buchwepheshe buvumela umshini ukubikezela ukuguga nokuhlela ukugcinwa kwawo.

Le ndlela yokuthatha isinyathelo ngokushesha isiza ukuvimbela ukuphuka okungalindelekile. Yehlisa isikhathi sokuphumula futhi igcine imigqa yokukhiqiza isebenza ngokushelela, ikhuphule ukusebenza okuphelele.

Ukuthuthwa Kwendle Okuthuthukisiwe kanye Nezinhlelo ze-CIP

Amasistimu e-Automated Clean-in-Place (CIP) aguqula ukuthuthwa kwendle. Lezi zinhlelo zisebenzisa ukulandelana okulawulwa ngekhompuyutha ukuphatha imijikelezo yokuhlanza ngokunemba. Lokhu kuzenzakalela kuholela ekongeni okubalulekile kwensiza.

Ukusetshenziswa Kwekhemikhali Okuthuthukisiwe: Uhlelo lukhipha inani eliqondile lama-ejenti okuhlanza adingekayo, lehlisa imfucuza.

Ukusetshenziswa Kwamanzi Okuncishisiwe: Imijikelezo yokuhlanza elawulwayo kanye namazinga okugeleza kusebenzisa amanzi amancane kunokuhlanza ngezandla.

Ukungaguquguquki Kakhudlwana: Ukuhlanza okuzenzakalelayo kunikeza inqubo ephindaphindwayo, engenaphutha ngaso sonke isikhathi.

Amasistimu Ombono Athuthukile

Izinhlelo zombono ezithuthukisiwe zisebenza njengamehlo omugqa wokugcwalisa. Amakhamera athola ngokuzenzakalelayo ukuvuleka komgqomo ukuqinisekisa ukuthi umlomo wombhobho wokugcwalisa umi kahle. Ngemva kokugcwalisa, isistimu ingakwazi ukubona izinkinga eziningi. Lokhu kubandakanya:

Ukuvuza noma imikhondo kawoyela emgqonyeni

Amakepisi angekho, agwegwile, noma awonakele

Amalebula asetshenziswe ngokungalungile noma awonakele

Lokhu kuhlola okubukwayo kuqinisekisa ukuthi imikhiqizo yekhwalithi ephezulu kuphela ephuma endaweni.

I-Robotic Palletizing kanye ne-De-palletizing

Amarobhothi enza ngokuzenzakalelayo ukuphakamisa okusindayo ekugcineni komugqa. Uhlelo lwe-robotic 5 Gallon Barrel Filling Machine lungabeka imiphongolo egcwele kuma-pallets ngesivinini esingaguquki nangokunemba. Lokhu kuzenzakalela kwandisa ukudlula ngokususa amabhodlela. Kuphinde kwakha indawo yokusebenza ephephile ngokususa abasebenzi emisebenzini enzima ngokomzimba, okunciphisa ubungozi bokulimala ngenxa yokuphakama okuphindaphindayo.

Ukukhetha umshini wokugcwalisa we-5 Gallon Barrel ofanele kuncike ezidingweni ezithile zenkampani. Ibhizinisi kufanele lihlaziye umthamo walo wokukhiqiza, isabelomali, kanye namasu okukhula.

Izihlungi ezizenzakalelayo zilungele ukukhiqizwa kwevolumu ephezulu (amayunithi angaphezu kuka-10,000 ngosuku), ukubeka phambili ukungaguquguquki nokonga umsebenzi wesikhathi eside.

Ama-semi-automatic fillers anikezela ngokutshalwa kwezimali okuphansi kokuqala kanye nokuvumelana nezimo okukhulu kwemisebenzi emincane.

FAQ

Yiziphi izimboni ezisebenzisa izigcwalisi zemiphongolo engamalitha ayi-5?

Le mishini isebenzela imikhakha eminingi. Abasebenzisi abajwayelekile bafaka izinkampaniemabhodleleni amanzi, amakhemikhali, ukudla neziphuzo, nezimboni zemithi. Baphatha izinhlobonhlobo zemikhiqizo ewuketshezi.

Ingabe ukulungiswa kuhlukile kokugcwalisa okuzenzakalelayo uma kuqhathaniswa ne-semi-automatic?

Yebo, isondlo siyehluka. Amasistimu azenzakalelayo ngokuvamile anezici zokuzihlola. Imishini ye-Semi-automatic idinga ukuhlanzwa okwengeziwe nokuhlolwa ngesandla ngu-opharetha ukuze kuqinisekiswe ukusebenza okufanele kanye nenhlanzeko.

Isikhathi sokuthumela: Nov-05-2025