A 5 Gallon Barrel Filling Machine comes in two primary types: automatic and semi-automatic. Each type serves different production needs based on the level of operator involvement.

Automatic fillers handle the entire filling process independently.

Semi-automatic fillers require an operator to place barrels and start each cycle.

Key Takeaways

Automatic fillers work best for big factories that make many products. They fill barrels fast and need fewer workers.

Semi-automatic fillers are good for smaller businesses. They cost less to buy and are easy to change for different products.

The best filler for you depends on how many barrels you need to fill and how much money you want to spend.

Comparing Automatic vs. Semi-Automatic Fillers

Choosing the right filler depends on a careful analysis of your production needs. Factors like speed, cost, labor, and flexibility will guide your decision. Let's break down the key differences between automatic and semi-automatic systems.

Production Speed and Volume

Production speed is often the most significant factor separating these two types of machines.

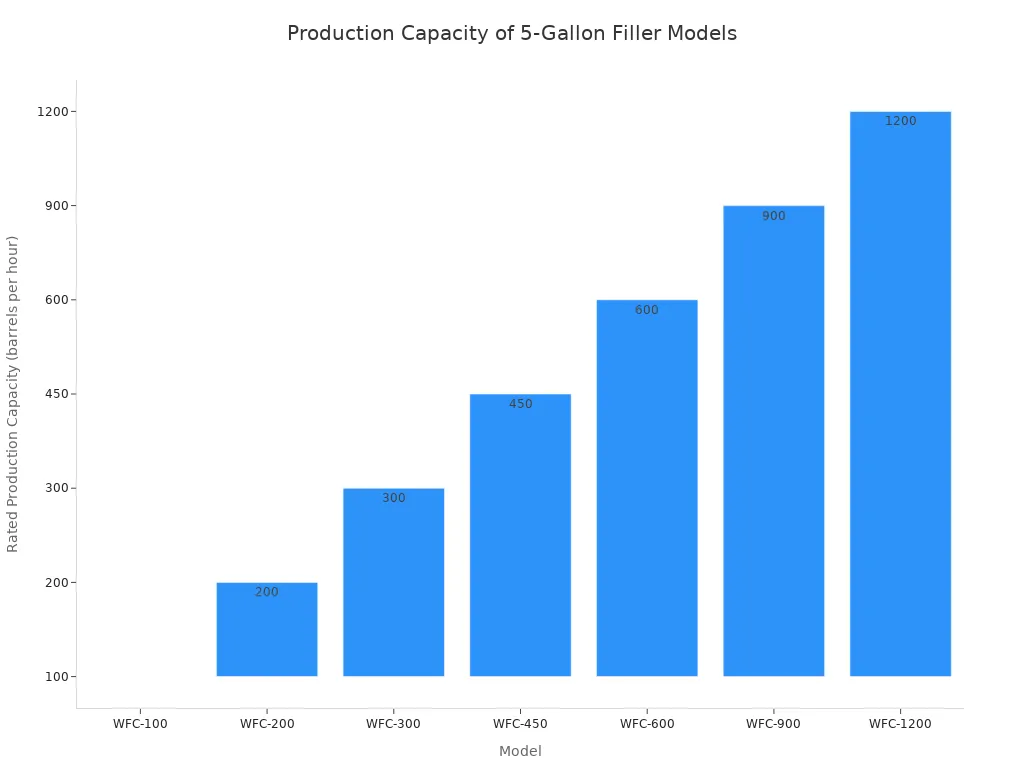

Automatic Fillers: These machines are built for high-volume manufacturing. They operate continuously with minimal interruption, achieving impressive output rates. Some advanced models can fill up to 1,200 barrels per hour (BPH), while others in a full production line can reach speeds of 2,000 BPH or more. High-speed rotary systems are ideal for large-scale operations that need to maximize efficiency.

Semi-Automatic Fillers: These fillers offer a good working speed for small to mid-scale operations. An operator manually controls the pace, which is naturally slower than a fully automated process. They are a cost-effective solution for businesses that do not require the high throughput of an automatic system.

The right choice depends entirely on your production volume.

Small-Scale Production: Startups and small businesses often find semi-automatic machines to be the most cost-effective option.

Mid-Scale Operations: Growing businesses benefit from semi-automatic systems that balance automation with manual control.

High-Volume Manufacturing: Large facilities in the chemical, pharmaceutical, or water bottling industries rely on fully automatic machines to maximize speed and efficiency.

Initial Cost vs. Long-Term ROI

The financial investment is a critical part of the decision-making process. While initial costs differ greatly, the long-term return on investment (ROI) tells a more complete story.

An automatic 5 Gallon Barrel Filling Machine represents a significant upfront investment, with prices for a full production line often ranging from $3,500 to $45,000. This cost can seem high, but it unlocks substantial long-term savings.

Most companies achieve a return on investment for automatic fillers within 18 to 24 months. This quick payback comes from major reductions in labor costs, less material waste, and higher production efficiency.

For example, facilities that upgrade to a fully automated line can reduce labor expenses by roughly 40%. One mid-sized food processor saved approximately $326,000 annually on wages alone after installing automated fillers, recouping their investment in just over a year and a half.

Labor Requirements and Operator Role

The level of human involvement is a core distinction between the two systems, directly impacting labor costs and operational roles.

A semi-automatic line requires operators to be actively involved in the process. A single line might need 4 to 6 workers, leading to annual labor costs that can exceed $200,000. The operator's responsibilities are extensive and include:

Placing empty barrels onto the filling station.

Initiating the fill cycle for each barrel.

Monitoring the process for errors.

Applying labels and moving filled barrels to the next station.

Performing simple machine maintenance and cleaning.

In contrast, a fully automatic 5 Gallon Barrel Filling Machine can reduce the labor requirement to just 1-2 supervisors per line. Some new systems have cut the necessary workforce in half compared to older lines. An operator's role shifts from manual labor to supervision, focusing on monitoring the system, managing settings, and addressing any alerts. This automation can lead to annual labor savings of $58,000 to $92,000 per line.

Filling Accuracy and Consistency

Consistency is key to product quality, brand reputation, and profitability. Automatic systems offer a clear advantage in this area.

Semi-automatic systems depend on the operator's attention and rhythm. This human element introduces a higher potential for error and inconsistency. Fully automatic machines, however, operate with computer-controlled precision, ensuring each barrel is filled to the exact same level every time. This difference is reflected in defect rates.

| Feature | Semi-Automatic Systems | Fully Automatic Systems |

|---|---|---|

| Defect Rate | 3-5% | 1-2% |

| Consistency | Lower | Increased |

Even small inaccuracies can have a large financial impact.

Overfilling leads to significant product loss over thousands of units, directly hurting the bottom line. Underfilling can damage customer trust, lead to product returns, and even create legal issues if products do not meet regulatory weight and volume requirements.

By minimizing human error, a 5 Gallon Barrel Filling Machine with full automation protects both your product and your profits.

Footprint and Space Requirements

The physical size of the equipment is a practical consideration for any facility.

Automatic Fillers: A fully automatic line is an integrated system that often includes conveyors, de-palletizers, cappers, and labelers. This requires a significant amount of linear floor space and careful facility planning.

Semi-Automatic Fillers: These are typically smaller, standalone machines. Their compact design offers greater flexibility, allowing them to be placed in facilities with limited space or integrated into existing layouts more easily.

Flexibility and Changeover Speed

If your business produces multiple products or uses different container sizes, flexibility is crucial. Here, semi-automatic fillers often have the upper hand.

Semi-automatic machines are generally easier and faster to change over from one product to another. Cleaning is straightforward, and adjustments for different barrel sizes are often simple. This makes them ideal for industries like craft beverages or specialty chemicals that require frequent short production runs.

Automatic fillers are masters of specialization, designed for long, uninterrupted runs of the same product. While modern systems have features to speed up changeovers, the process is typically more complex and time-consuming.

Changeover Comparison

| Feature | Semi-Automatic Filler | Automatic Filler |

|---|---|---|

| Changeover Speed | Generally faster and easier | Can be complex and time-consuming |

| Flexibility | High, ideal for short runs | Low, designed for long runs |

| Best For | Custom products, multiple SKUs | High-volume, single-product lines |

Small beverage manufacturers and nutraceutical companies benefit greatly from the flexibility of semi-automatic fillers, as it allows them to produce small batches and explore new product variations without major downtime.

Key Innovations for 5 Gallon Barrel Filling Machine in 2025

The technology behind barrel fillers is constantly advancing. By 2025, several key innovations will make these machines smarter, cleaner, and more efficient. These improvements help businesses boost productivity and ensure product quality.

Smart Controls and IoT Integration

Modern fillers are becoming more intelligent through the Internet of Things (IoT). Companies are integrating sensors and machine-learning models into their equipment. This technology allows the machine to predict wear and schedule its own maintenance.

This proactive approach helps prevent unexpected breakdowns. It reduces downtime and keeps production lines running smoothly, increasing overall throughput.

Enhanced Sanitation and CIP Systems

Automated Clean-in-Place (CIP) systems are transforming sanitation. These systems use computer-controlled sequences to manage cleaning cycles with precision. This automation leads to significant resource savings.

Optimized Chemical Usage: The system dispenses the exact amount of cleaning agents needed, reducing waste.

Reduced Water Consumption: Controlled rinse cycles and flow rates use less water than manual cleaning.

Greater Consistency: Automated cleaning provides a repeatable, error-free process every time.

Advanced Vision Systems

Advanced vision systems act as the eyes of the filling line. Cameras automatically find the barrel opening to ensure the filling nozzle is perfectly positioned. After filling, the system can detect a wide range of issues. These include:

Leaks or oil traces on the barrel

Missing, crooked, or damaged caps

Incorrectly applied or damaged labels

This visual inspection guarantees that only high-quality products leave the facility.

Robotic Palletizing and De-palletizing

Robotics automates the heavy lifting at the end of the line. A robotic 5 Gallon Barrel Filling Machine system can stack filled barrels onto pallets with consistent speed and precision. This automation increases throughput by eliminating bottlenecks. It also creates a safer workplace by removing workers from physically demanding tasks, which reduces the risk of injuries from repetitive lifting.

Choosing the right 5 Gallon Barrel Filling Machine depends on a company's specific needs. A business must analyze its production volume, budget, and growth strategy.

Automatic fillers are ideal for high-volume production (over 10,000 units/day), prioritizing consistency and long-term labor savings.

Semi-automatic fillers offer a lower initial investment and greater flexibility for smaller operations.

FAQ

What industries use 5-gallon barrel fillers?

These machines serve many sectors. Common users include companies in the water bottling, chemical, food and beverage, and pharmaceutical industries. They handle a wide range of liquid products.

Is maintenance different for automatic vs. semi-automatic fillers?

Yes, maintenance differs. Automatic systems often have self-diagnostic features. Semi-automatic machines require more manual cleaning and inspection by an operator to ensure proper function and hygiene.

Post time: Nov-05-2025