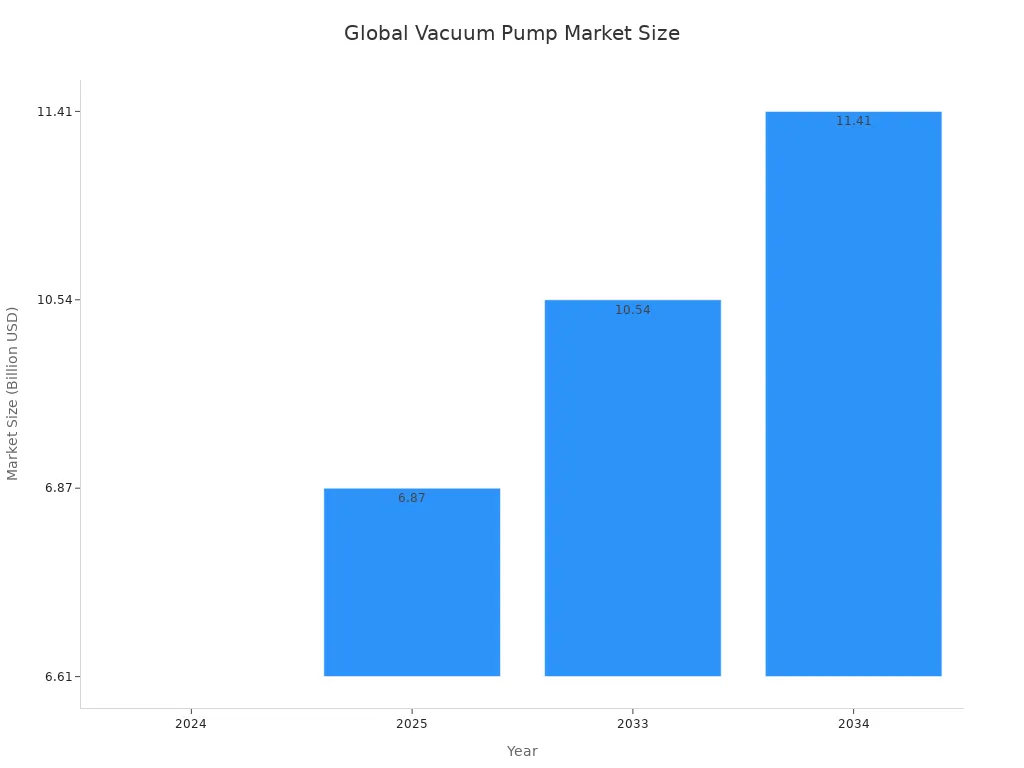

Tushen famfo yana ƙirƙira injin ta amfani da jujjuyawar juzu'i guda biyu, lobed rotors. Wadannan rotors suna tarko iskar gas a mashigar da kuma jigilar shi a fadin gidan famfo ba tare da matsawa na ciki ba. Wannan ci gaba, babban saurin canja wurin ƙwayoyin iskar gas yana rage matsa lamba, samun vacuums a matsayin ƙasa da 10⁵ mbar tare da goyon baya mai kyau. Ci gaba da ci gaban kasuwar fanfo na duniya yana nuna mahimmancinsa.

Yawancin sassa masu mahimmanci sun dogara daTushen injin famfo, ciki har da:

Masana'antar Semiconductor: Don matakai kamar jigon fim na bakin ciki da etching.

• Masana'antar sinadarai: A aikace-aikace kamar distillation da bushewa.

Masana'antar harhada magunguna: Don tacewa da daskare-bushewa.

Ayyukan Ciki na Tushen Vacuum Pump

Tushen injin famfo yana aiki akan ƙa'ida mai sauƙi amma mai tasiri sosai. Na'urarsa ta ciki tana motsa iskar gas daga mashigai zuwa mashigar ba tare da matsawa cikin ɗakin famfo ba. Wannan tsari ya dogara da motsin aiki tare na sassa da dama masu aiki cikin jituwa.

Zagayen Aiki Na Mataki Hudu

Ayyukan famfo yana faruwa a cikin ci gaba, zagayowar mataki huɗu wanda ke maimaita dubbai a cikin minti daya. Rotors na zamani na iya yin juyi a cikin sauri daga 3,000 zuwa 6,000 RPM. Wannan babban gudun yana ba famfo damar motsa manyan iskar gas da sauri.

Abin sha: Yayin da rotors biyu na lobed suna jujjuya su a gaba da gaba, aljihun sarari yana buɗewa a mashigar famfo. Gas daga ɗakin datti yana gudana cikin wannan ƙarar faɗaɗawa.

Warewa: Tip lobe na rotor ya wuce tashar shiga. Wannan aikin yana kama wani takamaiman ƙarar iskar gas tsakanin na'ura mai juyi da gidan famfo.

Canja wuri: Aljihun gas ɗin da ke daure da shi ana share shi a cikin gidan zuwa wurin fita. Babban fasalin Tushen injin famfo shine cewa baya damfara wannan iskar yayin canja wuri. Wannan aikin da ba a haɗa shi ba, ba tare da mai ba yana sa shi rashin kulawa ga ƙananan ƙura ko tururin ruwa.

Ƙarfafawa: Rotor ya ci gaba da juyawa, yana fallasa aljihun gas zuwa tashar fitarwa. Daga nan iskar gas ɗin ta faɗaɗa cikin layin da ke shaye-shaye, inda famfo mai goyan baya ke cire shi daga tsarin. Wannan sake zagayowar yana maimaitawa, yana ci gaba da motsa iskar gas daga mashigai zuwa mashigar kuma yana rage matsa lamba na tsarin.

Lura: Yayin da yake da inganci ga iskar gas da yawa, ikon tsotsawar famfon Tushen yana da ƙasa don iskar gas mai haske kamar hydrogen idan aka kwatanta da sauran nau'ikan famfo.

Mabuɗin Abubuwan da Aiki da Su

Ingantacciyar aikin famfo Tushen ya dogara da ƴan mahimman abubuwan da aka ƙera tare da madaidaici.

Rotors: The famfo yana da nau'i-nau'i biyu masu haɗaka, lobed rotors (sau da yawa siffa kamar siffa-takwas). Siffar, ko bayanin martaba, na waɗannan lobes suna shafar aiki kai tsaye. Zane-zane daban-daban suna ba da ciniki tsakanin saurin yin famfo da inganci. Helical rotors, alal misali, suna taimakawa rage bugun bugun jini da hayaniyar aiki.

| Nau'in Bayanan Bayani na Rotor | Amfanin Gudun Pumping | Adadin Amfani da Ƙarar |

|---|---|---|

| Novel elliptical | 1.5 sau sama da saman elliptical | Babban |

| Babban elliptical | Daidaitaccen aiki | Ya kusan 55% |

Gidaje (Casing): Wannan ita ce jikin waje wanda ke kewaye da rotors. An gina shi don tsayayya da bambance-bambancen matsa lamba tsakanin tsarin vacuum da yanayi. Abubuwan da ake amfani da su don gidaje da rotors sun dogara da buƙatun aikace-aikacen don juriyar lalata, ƙarfi, da farashi.

| Kayan abu | Mabuɗin Amfani | Aikace-aikace gama gari |

|---|---|---|

| Bakin Karfe | Ƙarfi mai ƙarfi, juriya mai kyau, mai tsada. | Gabaɗaya masana'antu, sinadarai, da sarrafa abinci. |

| Bakin Karfe | Kyakkyawan juriya na lalata, kaddarorin tsabta. | Pharmaceutical, semiconductor, da kayan aikin likita. |

| Aluminum Alloy | Fuskar nauyi, mai kyau thermal conductivity. | Aerospace, mota, da kuma šaukuwa famfo tsarin. |

Gears na lokaci: Ana zaune a wajen ɗakin famfo, kayan aikin lokaci suna da mahimmanci. Suna aiki tare da rotors guda biyu, suna tabbatar da cewa suna jujjuya su a wurare daban-daban ba tare da taɓa juna ko gidan ba. Wannan aiki tare yana da mahimmanci ga aikin ba tare da tuntuɓar famfo ba.

Shaft Seals: Hatimin hatimi suna hana iska daga zubowa cikin ɗakin datti kuma yana dakatar da mai daga gurbata aikin. Zaɓin hatimi ya dogara da matakin injin da ake buƙata da aikace-aikacen.

| Nau'in Hatimi | Makanikai | Mafi kyawun Ga |

|---|---|---|

| Hatimin Labyrinth | Yana amfani da hadaddun hanya don dakatar da kwarara; babu lamba. | Aikace-aikace masu sauri inda ake buƙatar lalacewa. |

| Hatimin Injini | Yana amfani da fuskoki biyu masu gogewa sosai, masu ɗauke da bazara. | Babban matsi, zafi mai zafi, da ƙananan buƙatun buƙatun. |

| Hatimin Ruwan Magnetic | Yana amfani da ruwan maganadisu don ƙirƙirar shamaki cikakke. | Manyan aikace-aikace masu buƙatar zubewar sifili. |

Muhimmancin Tsare Tsare-Tsare

Kalmar "clearance" tana nufin ƙananan, ƙididdiga rata tsakanin rotors da tsakanin rotors da gidaje. Wadannan gibin sune sirrin nasarar famfo. Suna ba da damar rotors suyi jujjuya cikin babban gudu ba tare da gogayya ba, wanda ke ba da fa'idodi da yawa:

Saurin farawa

Rashin wutar lantarki

Babban gudun fantsama

Ƙananan aiki da farashin kulawa

Duk da haka, dole ne a gudanar da waɗannan shares ɗin daidai. Yayin aiki, famfo yana haifar da zafi. Wannan zafi yana haifar da haɓakar abubuwan ƙarfe, tsarin da aka sani da fadada thermal. Yayin da rotors da gidaje ke faɗaɗa, ƙaddamarwa tsakanin su yana raguwa.

Gargaɗi: Idan izinin ya zama ƙanƙanta saboda haɓakar thermal ko haɗuwa mara daidai, rotors na iya yin hulɗa da juna ko gidaje. Wannan yana haifar da gogayya, ɓarna ɓangarori, ƙarar lodin mota, da yuwuwar kama famfo. Akasin haka, sharewar da ke da girma da yawa suna ba da damar iskar gas ya koma baya daga mashigar zuwa mashigai, wanda ke rage tasirin famfon sosai.

Injiniyan da ya dace da zaɓin kayan aiki suna tabbatar da cewa bututun injin Tushen yana kiyaye mafi kyawun sharewa a cikin kewayon yanayin zafin sa, yana ba da ingantaccen aiki mai inganci.

Kanfigareshan Tsari: Bayarwa vs. Famfon Matakai Masu Yawa

Tushen famfo mai ƙarfi ne mai ƙarfi, amma ba zai iya aiki shi kaɗai ba. Yana buƙatar ƙayyadaddun ƙayyadaddun tsarin don isa ga cikakken ƙarfinsa. Famfu yana motsa iskar gas da kyau amma baya danne shi don ya shanye kai tsaye cikin yanayi. Wannan iyakance yana buƙatar amfani da famfo mai goyan baya ko tsari mai matakai da yawa.

Me Yasa Bukatar Taimakawa Yake Bukatar

Tushen famfo yana buƙatar famfo mai goyan baya don ɗaukar sharar sa. Famfu na baya yana haɗawa zuwa mashin famfo na Tushen. Yana ɗaukar iskar gas ɗin da aka canjawa wuri kuma ya matsa shi zuwa matsa lamba na yanayi, yana kammala aikin fitarwa. Wannan haɗin gwiwar yana ba da damar tsarin don cimma zurfin vacuums yadda ya kamata. Zaɓin famfo mai goyan baya ya dogara da takamaiman aikace-aikacen da matakin injin da ake so.

Shin Ka Sani? Hakanan ana kiran famfo mai goyan baya famfo na farko saboda yana yin aikin ƙarshe na cire gas daga tsarin.

Nau'o'in fafutuka na yau da kullun sun haɗa da:

Famfon rotary mai hawa biyu

famfunan injin da aka rufe da mai

Mataki biyu nunin bawul inji famfo

Liquid zobe injin famfo

Yadda Pumps Multi-Stage Aiki

Don aikace-aikacen da ke buƙatar matsananciyar matsananciyar matsananciyar wahala, injiniyoyi suna haɗa famfo da yawa a jere. Wannan yana haifar da tsarin Tushen Vacuum Pump mai matakai da yawa. A cikin wannan saitin, hanyar famfo na farko yana ciyarwa a cikin mashigar na biyu, da sauransu. Kowane mataki na gaba yana rage matsa lamba. Har yanzu ana buƙatar famfo mai goyan baya na ƙarshe a ƙarshen sarkar don ƙyale iskar gas zuwa sararin samaniya.

Waɗannan tsare-tsare masu ƙarfi suna da mahimmanci ga manyan masana'antu da masu buƙata. Manyan aikace-aikace sun haɗa da:

Ƙirƙirar Semiconductor: Don matakai kamar Tsarin Tushen Sinadarai (CVD), Tushen Tushen Jiki (PVD), da etching.

Aerospace: A cikin dakunan kwaikwayo na sararin samaniya da gwajin kayan aiki.

Sabon Makamashi: Don kera fale-falen hasken rana da batura.

Tushen injin famfo ya yi fice a saurin iskar gas maimakon matsawa na ciki. Ƙirar sa mai sauƙi, mara lamba yana haifar da haɓaka mai ƙarfi don tsabta, aikace-aikace masu girma. Famfu na zamani yanzu suna haɗa injuna masu amfani da makamashi da na'urori masu auna firikwensin, suna tura aiki har ma da ƙarin masana'antu masu buƙata waɗanda ke buƙatar amintaccen tsarin vacuum.

Lokacin aikawa: Oktoba-28-2025